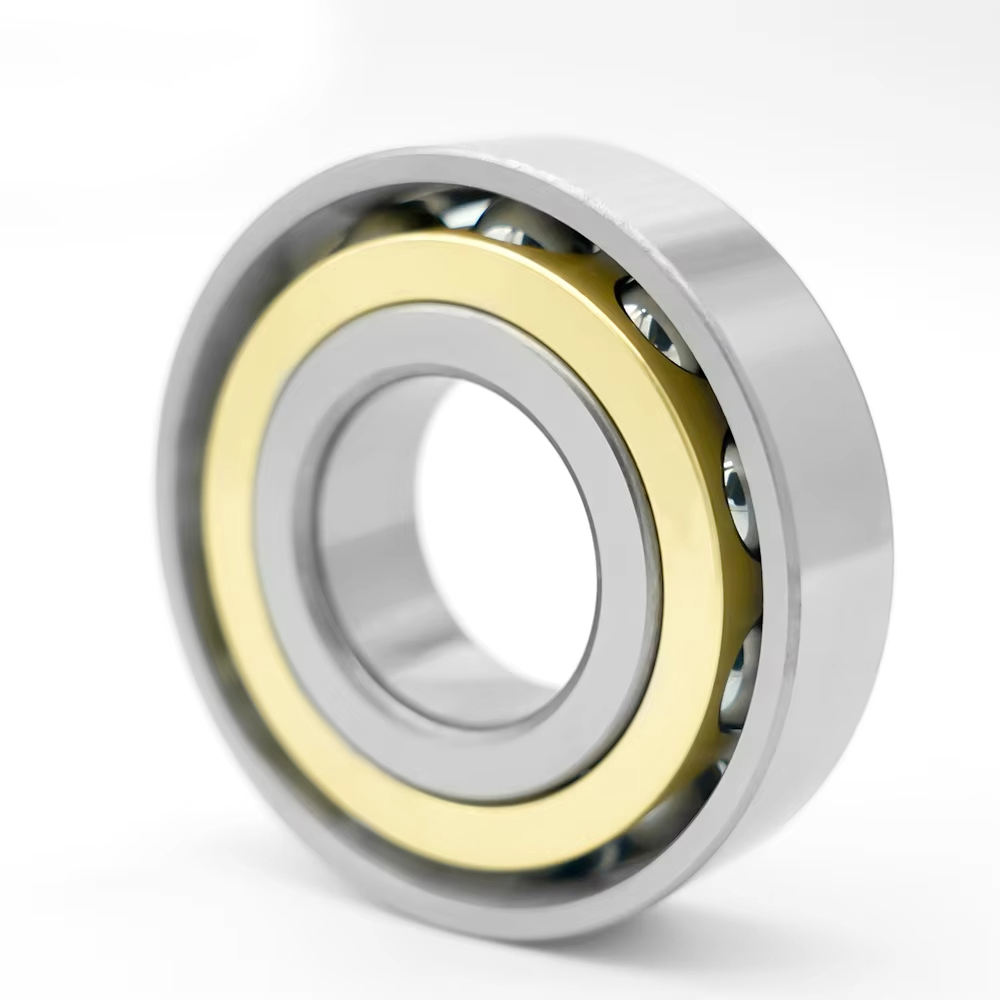

Single row angular contact ball bearings can only support axial loads in one direction. This type of bearing usually requires adjustment relative to another bearing. Its bearing ring has two shoulders, high and low, and cannot be separated.

This type can only withstand axial loads in one direction. When this type of bearing is subjected to pure radial load, since the action line of the rolling element load and the action line of the radial load are not in the same radial plane, internal axial component forces are generated, so they must be installed in pairs.

Product characteristics

It can bear radial and axial combined load or pure axial load at the same time;

Small running resistance and high limit speed;

High rotation accuracy;

Low noise and vibration;

Single row angular contact ballbearings can only bear one direction of axial force,usually used in pairs to balance the axial force.

Структура и дизайн

Provide a variety of structural types:single row angular contact ballbearing, paired angular contact ballbearing,double row angular contact ball bearing Bearings and four point contact ball bearings,и т. д..

Основные приложения

Machine tools,precision instruments,fluid conveying machinery,light indus- try machinery,и т. д..

Phenolic laminated fabric cages are very important for high-speed bearings. There are three cage guiding methods – inner land riding, outer land riding, and roller riding. Inner land riding has smaller moment of inertia and saves material but allows fewer rolling elements compared to outer land riding. Outer land riding has higher moment of inertia and can accommodate more rolling elements than inner riding. Roller riding generates less heat and noise at the same speed compared to inner and outer riding, but the structure is complex and difficult to manufacture, only suitable for molded plastic cages. For high-speed bearings, the cage radial wall thickness and width should be minimized, as long as strength permits. This not only reduces moments of inertia, but more importantly benefits heat dissipation and lubrication.

In summary, cage design is critical for high-speed angular contact ball bearings. Structural optimization helps meet strength, guidance, and inertia requirements while enabling heat dissipation, lubrication, and high-speed operation.

Shandong Bard Bearing Co., ООО.

Shandong Bard Bearing Co., ООО.